Concrete Refurbishment with SaniTarp® – Reliable Protection for Biogas Tanks

Aggressive gases like hydrogen sulphide attack concrete in biogas plants. SaniTarp® by AGROTEL protects tanks, fermenters, and digestate storage – for the life of the tank.

Why Concrete Refurbishment is Essential in Biogas Plants

Concrete refurbishment is crucial for the safety and economic operation of biogas plants. Aggressive gases – especially hydrogen sulphide – attack concrete surfaces in fermenters, secondary digesters, and digestate storage. Without sufficient concrete protection, corrosion, spalling, and costly downtimes can occur. Timely tank refurbishment safeguards the structure, extends the life of the plant, and ensures long-term operational reliability.

SaniTarp® – The Patented Concrete Renovation Membrane

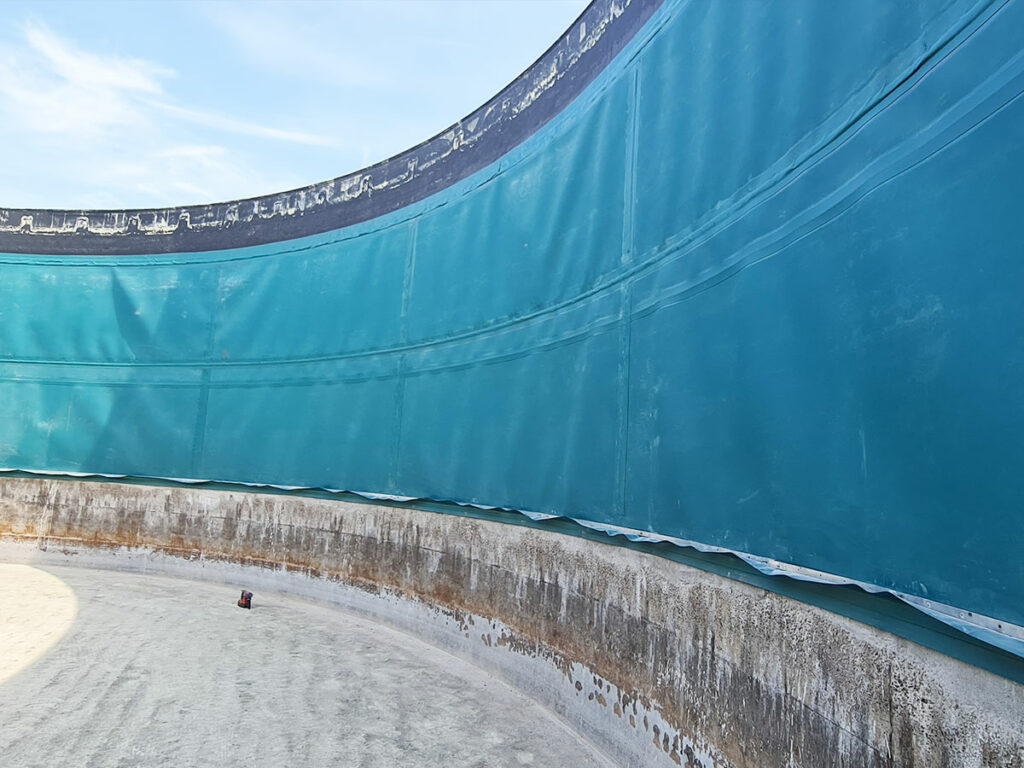

SaniTarp® is a patented concrete refurbishment membrane by AGROTEL, applied to the interior wall of biogas tanks. It provides tank lining to refurbish and protect the tank wall permanently from aggressive media.

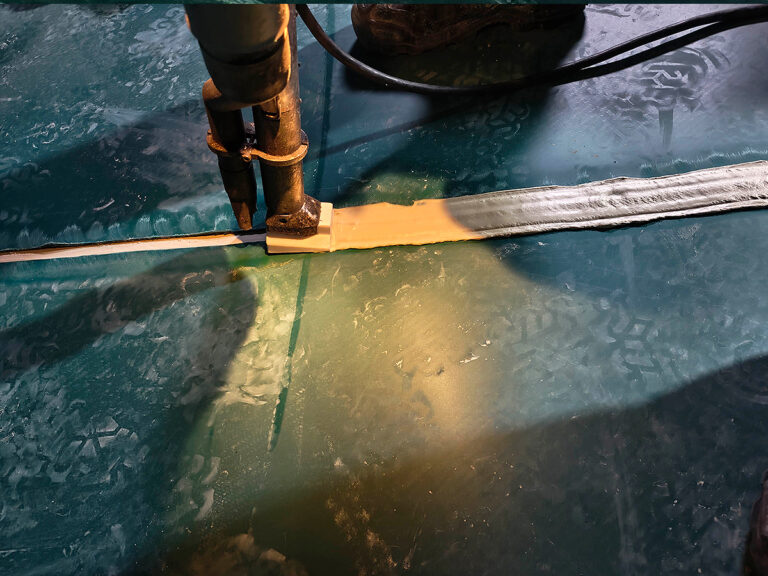

The membrane features a PP coating, which is gas-tight as well as being chemically and thermally resistant. A strong fabric backing ensures mechanical stability. Custom-made solutions guarantee a perfect fit and unbeatable protection. Corrosion-resistant installation and professional welding ensure that SaniTarp® safeguards the tank wall, supports, and crown for the lifetime of the tank.

Professional Installation for 100% Sealing

Installation is carried out exclusively by experienced AGROTEL technicians. Welded joints ensure completely sealed tank walls, resulting in durable protection, fewer repairs, and stable concrete – without affecting plant operations.

Benefits for Operators

SaniTarp® reliably protects concrete and increases the economic efficiency of the plant by minimizing downtimes.

The special membrane can be installed in any weather conditions. This enables rapid renovation without long interruptions to plant operation, meaning that biogas production can continue without any significant losses.

Custom-fitted panels ensure precise coverage, and tests by the Fraunhofer Institute confirm maximum reliability.

The concrete protection membrane is applied to the area of the tank wall that is permanently exposed to gas and, thanks to its high-quality material components, can withstand chemical attack over a long period of time. SaniTarp preserves the function and stability of your plant for years to come.

Conclusion: SaniTarp® provides a technically proven, economical, and durable concrete protection solution. The membrane reliably shields concrete, reducing downtime and extending the lifespan of biogas plants – for the life of the tank.

SaniTarp® - Image gallery

FAQ`s

What is SaniTarp®?

A patented concrete refurbishment foil for retrofitting and protecting biogas tanks.

Why refurbish biogas tanks?

Insufficient concrete protection can lead to corrosion, damage to fermenters or digestate storage, and costly downtimes.

How long does SaniTarp® last?

When professionally installed, SaniTarp® lasts for the lifetime of the tank.

Can concrete protection be integrated during new construction?

Yes, with WireTarp®, new biogas tanks can be permanently protected from the outset.

Do you want to protect your biogas tank from day one?

Then integrate our patented WireTarp® concrete protection foil into your biogas tank during construction.