Concrete refurbishment for existing biogas tanks: SaniTarp

AGROTEL SaniTarp concrete refurbishment membrane is an innovative and proven solution for the retroactive concrete renovation of biogas tanks. It offers reliable protection against corrosion, extends the service life of the plant, and contributes to efficient and sustainable biogas production.

Concrete and tank renovation in biogas plants

We use our special membrane to repair damaged concrete surfaces and coatings in fermenters, slurry tanks, and gas storage facilities, protecting your plant from chemical attack. The membrane can be added to existing plants at a later date.

SanitTarp concrete refurbishment – benefits

- Reliable protection for concrete surfaces

Increased cost-effectiveness of your plant - Prevention of downtime

Weather-independent installation - Protection of the tank wall, tank support, and tank crown

Customized packaging - Absolute adhesive strength and tightness confirmed by the Fraunhofer Institute

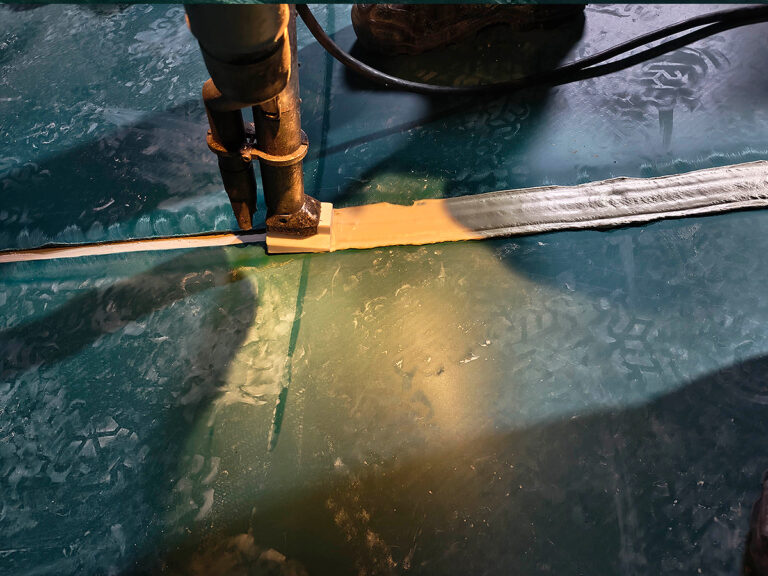

- Professional welding by our specialist staff

Weather-independent refurbishment

SaniTarp enables you to renovate your biogas plant quickly and flexibly, regardless of weather conditions. The special foiling can be installed in any weather, allowing you to maintain your plant without delay.

Optimum price performance ratio

AGROTEL SaniTarp offers impressive cost-effectiveness. Compared to alternative renovation methods, SaniTarp is a cost-effective and efficient solution for existing biogas tanks.

Reliable corrosion protection

SaniTarp concrete protection provides retroactive and lasting protection for concrete walls in biogas tanks against corrosion, thereby preserving the function and stability of your plant for years to come.

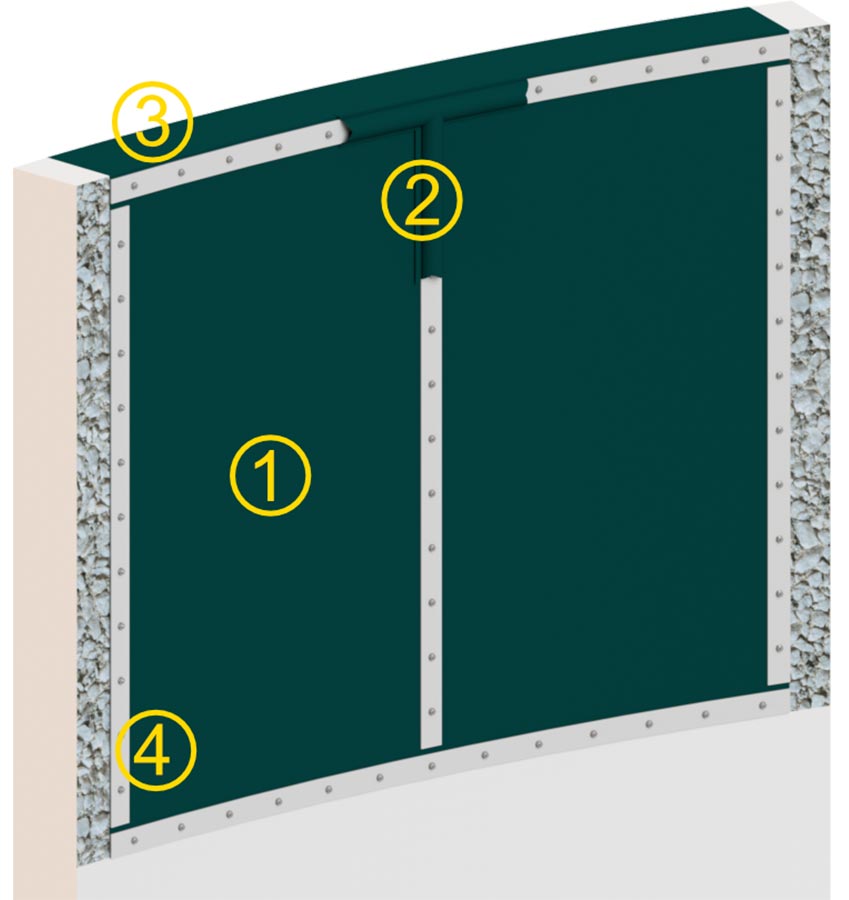

Membrane for concrete refubishment - Construction

1 SaniTarp concrete repair membran

2 Weld over mounting

3 Crown protection

4 Stainless steel (1.4571) fixings

SaniTarp concrete renovation membrane - Material

PP-coating

SaniTarp consists of a gas-tight and media-resistant PP coating. The complete sealing of the concrete elements prevents further corrosion and forms long-term protection.

Fabric base

A strong fabric backing ensures the mechanical stability of SaniTarp and meets all requirements in the harsh environment of a biogas plant. The film is fastened and welded in a corrosion-resistant manner, providing a sustainable basis for the long-term protection of your plant.

Strong resistance

SaniTarp lines the area of the container wall that is permanently in contact with gas. Thanks to high-quality material components, it can withstand acid attack over an extended period of time.

Chemical and thermal protection

Hydrogen sulphide causes serious damage to concrete walls in inadequately protected fermenters or secondary fermenter tanks. The polypropylene concrete refurbishment protection membrane protects your tank from these attacks.

Reliable protection against corrosion

Tank refurbishment with SaniTarp can take place in all weather conditions. The resistant membrane is fixed with stainless steel fasteners which are also non-corrosive. Thanks to the short installation time, the tank can be quickly put back into operation.

Concrete refurbishment for your biogas plant: details and advantages

Focus on cost-effectiveness

SaniTarp extends the service life of your biogas plant and minimizes further expensive renovation measures in the future. This allows you to reduce your operating costs while increasing the efficiency of your plant.

Customized solutions

We manufacture SaniTarp exactly to your specifications to ensure an optimal fit and maximum protection.

Reduction of downtime

The quick and easy installation of SaniTarp enables rapid renovation without long interruptions to plant operation. This allows you to continue your biogas production without any significant losses.

Fachgerechte Montage

Our experienced specialists ensure professional installation and sealing of the SaniSan membrane, providing you with a durable and secure solution.

References - SaniTarp

Our SaniTarp concrete protection membrane is used on concrete walls of biogas plants that are affected by corrosion.The SaniTarp concrete renovation membrane from AGROTEL CenoTec has already proven itself in numerous biogas plants and impresses with its high effectiveness and reliability in the fight against corrosion.

FAQ`s

How does concrete renovation with SaniTarp work?

The SaniTarp membrane is professionally installed on the inner concrete wall and welded to be gas- and media-tight. Thanks to its PP coating and stable fabric backing, it provides a durable protective layer against aggressive gases and acids.

For which types of containers is SaniTarp suitable?

D

AGROTEL’s SaniTarp concrete renovation film is suitable for renovating corrosion-damaged concrete walls in various types of containers used in biogas plants.

Typical areas of application:

- Fermenters: The membrane is also suitable for renovating concrete walls in fermenters. It protects the container wall from attack by aggressive gases, thus ensuring the safe storage of biogas.

- Post-fermenters: SaniTarp prevents corrosion and deposits caused by aggressive fermentation substrates and hydrogen sulfide in post-fermentation tanks.

- Final storage

- Slurry tanks

We would be happy to provide you with comprehensive advice on SaniTarp and prepare an individual quote for the renovation of your biogas plant. Feel free to contact us at any time to find out more!

What advantages does SaniTarp offer compared to other renovation methods?

AGROTEL’s SaniTarp concrete renovation membrane offers numerous advantages over other renovation methods for corrosion-damaged concrete walls in biogas plants:

1. Effective corrosion protection:

- Long-term and reliable sealing: SaniTarp forms a gas-tight and media-resistant barrier against aggressive substances such as fermentation substrates and hydrogen sulfide, which cause corrosion.

- Prevents cracks and spalling: The membrane effectively protects the concrete from mechanical stress, thus maintaining the stability of the plant.

2. Cost-effectiveness and durability:

- Cost-effective solution: SaniTarp is significantly more cost-effective than alternative renovation methods such as replacing concrete walls.

- Long service life: The membrane is UV-resistant, weatherproof, and characterized by high durability.

- Increased efficiency of the biogas plant: A renovated and well-maintained biogas plant increases its cost-effectiveness.

3. Flexibility and easy installation:

- Quick installation: SaniTarp can be installed quickly and easily in an existing biogas plant.

- Weather-independent installation: The membrane can be installed in any weather, so that renovation can be carried out without delay.

- Customization: SaniTarp is made to measure and thus adapts perfectly to the specific requirements of your biogas plant.

How long does SaniTarp provide protection?

Thanks to high-quality polypropylene material, corrosion-resistant stainless steel fasteners, and robust construction, the protective layer is durable even under constant contact with aggressive media.

Is SaniTarp customized?

Yes, the film is custom-made to fit the dimensions of the respective system perfectly and ensure optimal protection.

How quickly can a tank be put back into operation after refurbishment?

Thanks to quick and easy installation, the tank can be put back into operation shortly after assembly, minimizing downtime.